Energy

Decarbonizing the Energy Sector with Ultra-Efficient Heat Exchangers

The energy sector depends on efficient thermal management solutions to optimise the performance and longevity of critical systems, including power generation, renewable energy, and waste heat recovery. Heat exchangers in this industry must offer superior thermal performance, robust construction, and adaptability to various fluids and operating conditions. Efficiency, durability, and reliability are essential to contribute to enhanced energy production, reduced operational costs, and improved sustainability.

The industry has traditionally depended on conventional heat exchangers, which are bulky and make these systems large or inefficient. We are working with our partners to develop game-changing heat exchangers for the decarbonisation of various energy systems.

Here are some of the applications of our compact thermal solutions.

Microturbine recuperators

Microturbines offer versatility in energy applications, serving as CHP systems and EV range extenders. In CHP, they generate electricity while capturing waste heat for enhanced efficiency. As range extenders, microturbines charge EV batteries on-the-go, overcoming battery range limitations. Their compact design, fuel flexibility, and low emissions make them ideal for sustainable energy solutions.

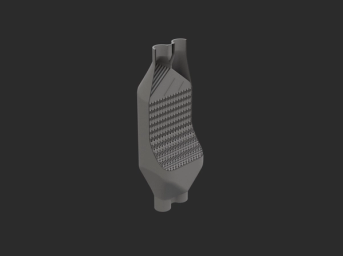

Recuperators play a vital role in microturbine and waste heat recovery, improving efficiency by recovering heat from exhaust gases. They preheat incoming air, improving combustion efficiency and reducing fuel consumption and emissions. Morpheus Designs’ recuperators, compactly designed, use high-temperature nickel-based alloys for operation up to 900°C, ensuring seamless integration into microturbine systems with excellent creep and corrosion resistance.

Functions:

Uses the exhaust hot gas from turbine to heat the incoming compressed air thus increasing microturbine efficiency

SCO2 waste heat recovery heat exchangers

Supercritical carbon dioxide (sCO2) heat exchangers are key components in advanced power generation systems utilising sCO2 as a working fluid. Operating under supercritical conditions, these heat exchangers enable efficient heat transfer, contributing to high overall system efficiency. Known for their compact design and unique thermophysical properties, sCO2 heat exchangers play crucial roles in advanced power cycles such as sCO2 Brayton or ALAM cycles.

Their applications include power generation, waste heat recovery, and heat pumps. Efficient thermal management, enabled by these heat exchangers, ensures reliable and continuous operation in high-temperature and high-pressure environments.

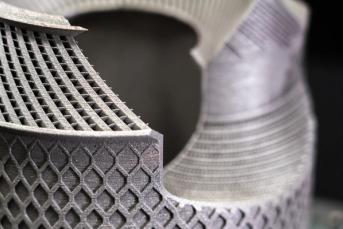

Morpheus Designs SCO2 heat exchangers use high strength and temperature materials to withstand extreme conditions, emphasising their importance in the development of next-generation, energy-efficient power generation technologies.

Functions:

sCO2 heat exchangers facilitate the transfer of heat between different fluid streams, such as Exhaust gas vs sCO2, allowing for efficient energy conversion processes.

Hydrogen precooler for refuelling stations

During the refuelling of hydrogen into high-pressure storage tanks, the fluid must be cooled to temperatures as low as -40°C before entering the vehicle's fuel tank. This cooling occurs in a heat exchanger while the hydrogen is at pressures up to 900 bar. Various fluids, such as nitrogen, CO2, and other suitable coolants, can be used to cool the hydrogen. The requirements for the heat exchanger in this process are stringent: it must be pressure-resistant, compact, and provide high thermal performance to ensure fast refuelling with high mass flow rates.

A key advantage of our AM heat exchangers is their compactness, efficiency, and low pressure drop, significantly reducing the envelope package. We use our design expertise to prioritise structural integrity and thermal performance through rigorous analysis and testing, delivering H2 coolers with unparalleled size and weight efficiency. The core structures are specially engineered to equalise pressure within the heat exchanger and avoid localised stress points.

Heat pump heat exchangers

The UK Heat Pump Ready Programme fosters the development of innovative solutions within the heat pump sector. As a crucial technology for decarbonizing homes, heat pumps are essential for helping the UK meet its commitment to achieving net zero by 2050. Currently, heating accounts for about 37% of total UK carbon emissions when including industrial processes.

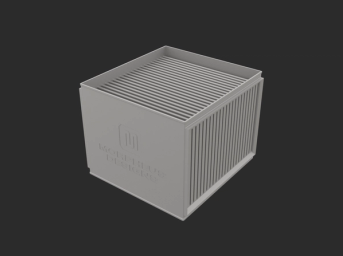

Heat pump heat exchangers are vital for thermal energy transfer and system performance in residential, commercial, and industrial sectors. One key challenge is their size exacerbated by limited spaces available at homes.

To address these challenges, we have developed innovative heat exchangers using additive manufacturing for these applications where size, compactness and high effectiveness are crucial for the system performance. Our models are tuned to optimise the full system using a range of operating conditions. Well-designed compact heat exchangers contribute to overall system efficiency, environmental sustainability, and the successful utilisation of low-grade heat for power generation.

These solutions are also applicable to Organic Rankine Cycle (ORC) heat exchangers, which are essential for many heat pump systems. They are particularly suited for low-temperature heat sources, enabling the efficient recovery of waste heat to generate electrical power and thus increasing overall system efficiency. The basic principle of an ORC system is essentially the reverse of a heat pump. While heat pumps use electrical power to produce thermal energy for various applications, an ORC system utilises heat energy to generate electricity. The ORC evaporator absorbs waste heat, vaporising the refrigerant, which then drives an expander to generate electricity. The condenser then transfers heat to another fluid, causing the working fluid to condense and allowing the cycle to repeat in a closed loop.